Why are automatic ethanol fireplaces with BEV technology a few times more expensive than manual ones?

Knowing the low prices of manual bio-fireplaces from DIY shops, the price of 4550 EUR (excl. VAT) for a Planika automatic insert may come as a surprise. To understand the components of this price and why it is worth investing in safety, read how the world’s most modern and advanced ethanol fireplace inserts are made.

What types of ethanol fireplaces are there?

All types of bio-fireplaces can be installed indoors without a chimney or other hard connections. They are an excellent alternative to gas fireplaces and a convenient solution for those who want to easily install a fireplace with a real fire.

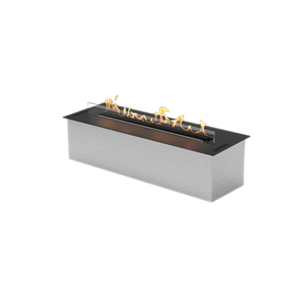

There are two types of ethanol fireplaces on the market – manual and innovative – automatic. Manual devices are open tanks in which ethanol is burned. The automatic ones with BEV (Burning Ethanol Vapours) technology produce alcohol vapours that are dispensed and burned in the burner. The combustion process is controlled by a microprocessor and safety sensors.

Combustion in manual fireplaces is incomplete and the heated ethanol evaporates into the room. In automatic ones, 100% of the vapour produced is burnt and the unused fuel remains in a sealed container, while minimising any odour. A special European commission is in the process of developing separate standards for manual and automatic bio-fireplaces. Only automatic bio-fireplaces guarantee complete safety.

How much do automatic ethanol fireplaces cost?

The FLA3 is Planika’s flagship fireplace, available in 6 lengths. Its price starts at 4550 EUR (excl. VAT) for a 790 mm long insert. Planika also offers smaller, simpler fireplaces also using BEV technology. The smallest insert, SENSO, costs 1200 EUR (excl. VAT).

ETHANOL FIREPLACE INSERTS

-

Senso Burner5.203,00 zł

Senso Burner5.203,00 zł -

FLA4 790 Burner27.632,00 zł

FLA4 790 Burner27.632,00 zł

Automatic ethanol fireplaces with advanced BEV technology

BEV stands for Burning Ethanol Vapours. This is the name of the technology that engineers at Planika have developed and patented. Automatic fireplaces were developed to eliminate the disadvantages of manual fireplaces and potential user errors. When dealing with a real fire, no compromises can be made on safety.

To refuel the automatic fireplace you will need an automatic pump that communicates with the device to pour the correct amount of fuel. Sensors check that the fuel tank is sealed and that the housing temperature is not too high. The fireplace automatically shuts off if it is overheated, tilted or shaken (in earthquake areas this is particularly important). You can control the height of the fire and the fuel level and the fire is started by an app on your phone or by remote control. Comparing this to the automotive world is a Mercedes among ethanol fireplaces.

Production costs of safe ethanol fireplaces

All components used in the production of Planika fireplaces come from European markets and the USA. Although their cost usually turns out to be higher compared to available replacements from China, the manufacturer can have a real influence on their quality and repeatability.

For the same reason, the company has also developed its machinery and employed specialists. Amongst other things, they are responsible for the steel laser cutting, the construction and welding of housings and tanks or powder coating. They also double-check their stability and the tightness of the tanks on site.

In automatic fireplaces, the most important components are the electronic components and the microprocessor that controls the fireplace. In the first stage, all components used in Planika fireplaces are tested separately. Then each fireplace is tested and calibrated after assembly. Another test is carried out before shipping. Also, the sensors are double-protected; should one of them stop working, its role is taken over by another. All the quality checks have a direct impact on the production cost of the fireplaces and subsequently on their final price.

The in-house factory is a guarantee of producing safe products. In the last 5 years, Planika has sold more than 25,000 fireplaces to countries all over the world (most of them to the United States). Not one of them has caused an accident.

In addition, manufacturing in-house allows Planika to reduce lead times and gives it the ability to react dynamically to market changes. While competitors have to deal with downtimes, e.g. due to pandemics, production continuity is ensured at Planika.

The seemingly high price of ethanol fireplaces

Automatic fireplace inserts are more expensive than other types of fireplaces, but their installation cost is lower. Adding the two costs, it turns out that the prices of the different types of fireplaces are quite similar.

Fireplaces with automatic ethanol-burning technology do not need a chimney or any piping supply. The only thing an ethanol fireplace needs is a suitable housing. Its cost starts at 600 EUR. The housing can be finished with decorative facings. A FORMA fireplace allows the use of any material, including wood.

Let’s compare the installation costs of other fireplace types.

The price of an average wood-burning stove is 900-1200 EUR. A fireplace with a water jacket costs 2000-2500 EUR. The average cost of installing a wood-burning fireplace is 2200-4500 EUR. For a fireplace with a water mantle, it is 5000-6000 EUR.

A high-quality gas fireplace costs 2700-3500 EUR and its installation costs 2500-6200 EUR.

In addition to the installation costs for gas and wood-burning fireplaces, there are also permit fees and annual inspection costs for the chimney and/or the installation. Ethanol fireplaces do not require building acceptance or regular maintenance, so they do not create these costs.

Research and development of automatic fireplaces

Planika is the developer of the globally innovative ethanol fireplace. The company has been on the market for 20 years and started out as a manufacturer of manual fireplaces. The decision to develop the technology in the direction of safety proved to be the only right one. The first models with automatic combustion appeared in 2010 and since then the technology has been continuously developed. Development work continues and each successive generation of BEV technology introduces additional improvements.

Fireplaces tailored to the project

Fireplaces with BEV technology are popular in modern interior design because they adapt flexibly to the design – they can be used on high floors of buildings or in commercial spaces. It is also fashionable to install an ethanol fireplace under the TV, which is also possible with automatic fireplaces.

Planika offers fire lines in various lengths from 30 cm to 250 cm. Fireplaces can be installed in a wall with any number of glazed sides and selected finishes. Designer free-standing models are also available, which can be used as soon as they are plugged in.